In the production of goods, especially monolithic goods, the role of fixtures is very important. They are necessary in the mechanical processing process, helping to improve the level of mechanics and automation, making the production process more accurate and faster. What is the design of processing fixtures? What is their role in production? Let’s learn about the knowledge surrounding the design of processing fixtures, methods and reputable service providers with Eintek.

Contents

What is a machining fixture?

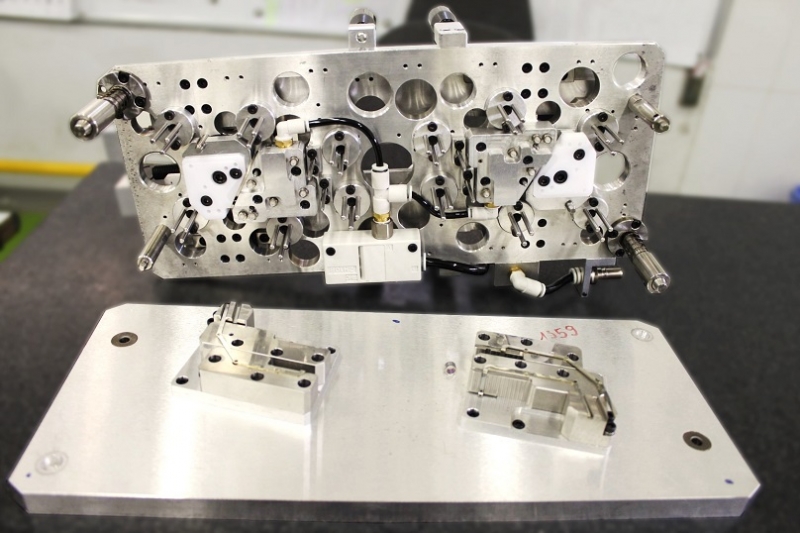

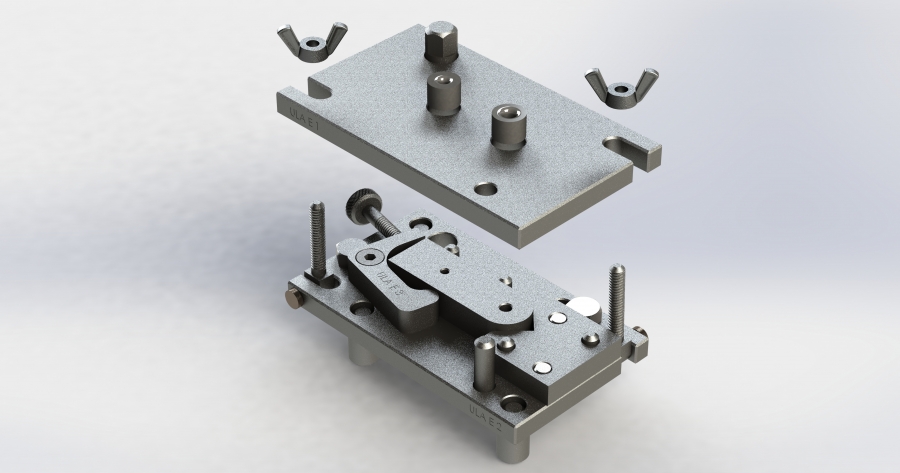

Machining fixtures are tools that help check, fix, and assemble mechanical products, used to determine the relative position of the workpiece to the cutting tool. At the same time, keep the workpiece in the correct position according to the requirements of the machining worker.

Benefits of machining fixtures in mechanics?

Used to quickly and accurately determine the position of the workpiece on the machine relative to the machine and cutting tool. Used to guide cutting tools in drilling, boring, boring machines, etc. Increase the speed of mechanization and automation of production. Expand the technological productivity of machine tools. Fix the tool so it does not move or move from its original position.

Some types of processing fixtures

Lathe fixture

Lathe machining fixtures have rotating workpieces or fixed workpieces, using rotating tools. Lathe fixtures are often used to hold and align mechanical products, avoiding deviation during the machining process. With a basic structure including a tool table (workpiece fixing table), a roller head, a clamping mechanism, a mounting part, and an indexing mechanism.

Drilling fixture

Drilling fixtures used on drilling machines help workers determine the exact position between the workpiece and the cutting tool. In addition, auxiliary tools are used to hold the workpiece firmly during machining such as drilling, reaming, and boring.

Milling fixture

Milling fixture must be rigid and clamp tightly because when milling there will be strong cutting pressure, large vibration causing the product to shift. The basic structure of the milling fixture includes positioning mechanism, tool comparison, indexing mechanism, clamping mechanism, copying mechanism and machine table.

Broaching fixture

Mechanical products that need to be machined precisely need a broaching fixture to hold and fix. The broaching fixture structure is quite simple, often using a silver-shaped or flange-shaped part to position the workpiece. When broaching grooves, there is an additional indexing mechanism.

Where is a reputable place to design processing fixtures?

Using the best machines and highly skilled machining engineers with many years of experience, Eintek will help customers find solutions for your mechanical processing process. We accept design of machining fixtures from simple, small orders to mass design orders that require high precision. Always provide quality products, according to requirements, on time with the most reasonable price.

*** See more:

Contact:

EINTEK ENGINEERING CO., LTD

Address: No 02, Street 07, Long Binh ward, Ho Ci Minh city

Email: info@eintek.com.vn

Mobile: (+84) 944 244 468

Website: https://eintek.com.vn/