What is fixture processing and where is the reputable unit providing fixture processing services, let’s find out with Eintek in the article below!

Contents

Jig processing

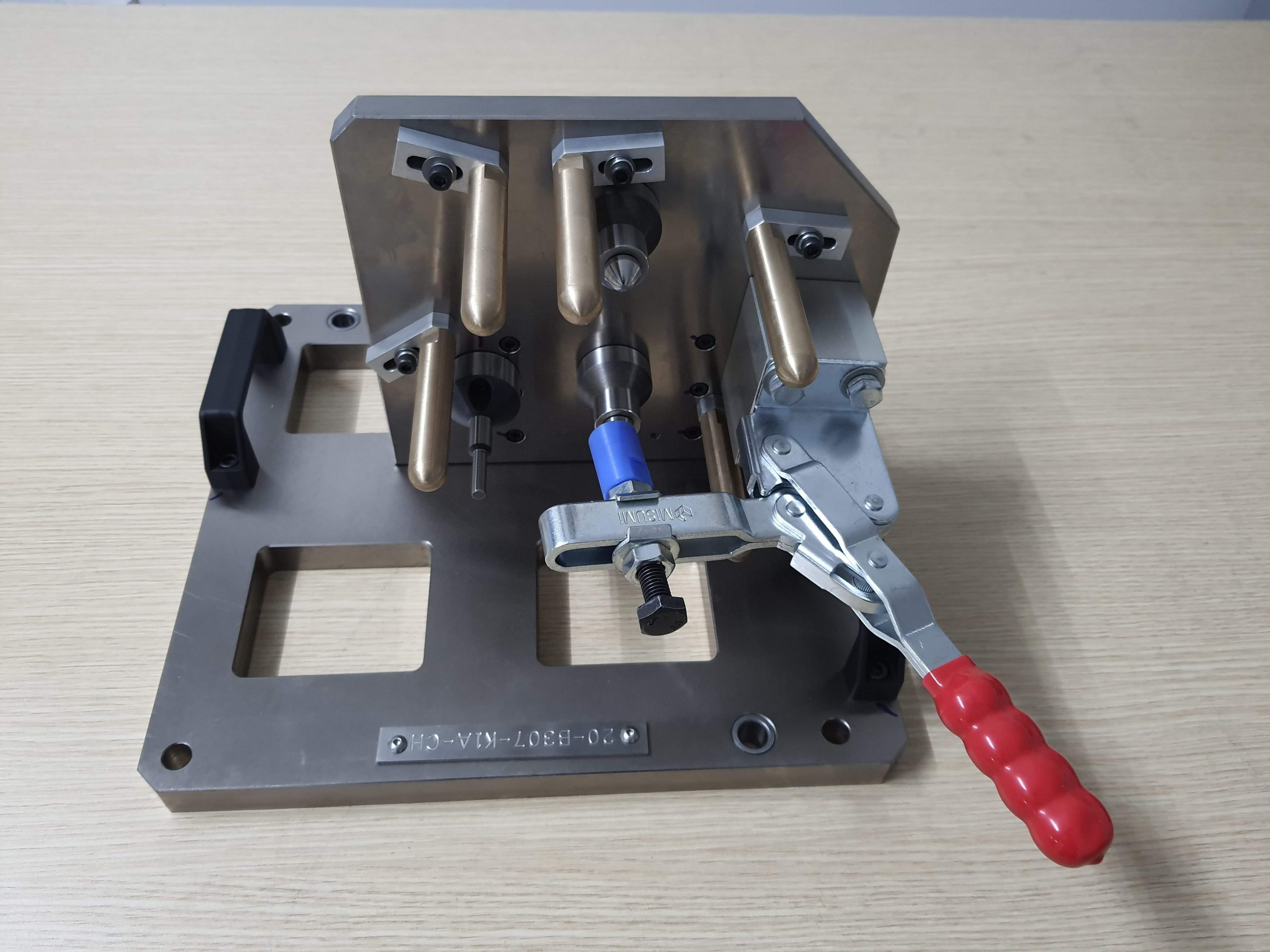

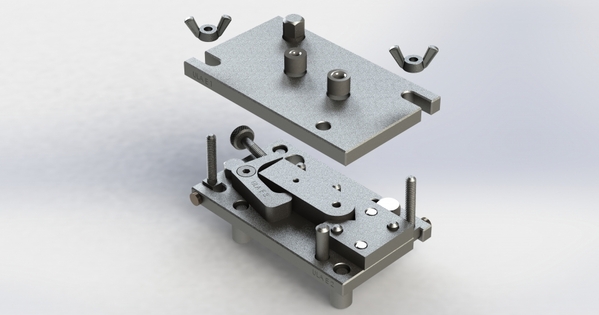

Mentioning mechanics is mentioning processing, machines and methods to process a part or a group of parts. To solve problems in mechanical processing, what we need to pay attention to is the ability and important role leading to the formation of product quality in the production process, creating products. Fixtures are necessary technological equipment in the process of mechanical processing, testing and assembling mechanical products. Therefore, the processing of fixtures requires extremely high technical requirements and precision to produce high quality products and have long-lasting durability.

Learn about jigs and jig processing

What is a fixture?

Classification of machining fixtures

- Assembly fixtures: Assembly fixtures are fixtures used to determine the position and clamp the part, including universal assembly fixtures and specialized assembly fixtures.

- Inspection fixtures: Inspection fixtures are used to evaluate the accuracy or surface quality of parts and products during the machining process. Inspection fixtures are divided into two types: static inspection fixtures and dynamic inspection fixtures.

- Machining fixtures: Machining fixtures are technological equipment to determine the exact position of the workpiece relative to the cutting tool, and at the same time maintain that position throughout the machining process.

Uses of jigs

Jigs are often very small in size in a machine but they provide extremely important functions:

- Locate and position the workpiece relative to the machine and cutting tool

- Clamp and fix the position of the positioned workpiece, preventing external forces from shifting or shaking

- Locate and guide the cutting tool

- Create additional motions to process complex surfaces, take advantage of and expand the technological capabilities of the machine

- Help to position the workpiece consistently and uniformly

- Reduce auxiliary time and machine time

- Reduce the labor intensity of workers and the skills of the operator

- Eliminate positioning by marking, punching, aligning, etc.

- Easily, quickly and always accurately locate, support and clamp the workpiece in line with the cutting tool

- Increase productivity and maintain consistent product quality

- Improve the technological capabilities of the machine tool

- Reduce overall machining costs and also increase interchangeability

Find a reputable unit providing fixture processing services

Why should you process fixtures at reputable units?

You should choose to process fixtures at reputable, professional processing facilities because reputable units will ensure you experience the best service with good product quality, with long-term use. Besides, using fixture processing services will ensure quick completion time and save a lot of costs.

Reasons to choose fixture processing service at Eintek

*** See more:

Contact:

EINTEK ENGINEERING CO., LTD

Address: No 02, Street 07, Long Binh Ward, Ho Chi Minh city

Email: info@eintek.com.vn

Mobile: (+84) 944 244 468

Website: https://eintek.com.vn/