The phrase “mechanical processing” is mentioned a lot in today’s life. What is the actual mechanical processing? What types of mechanical processing are there in Binh Duong? Let’s find out with Eintek through this article!

Contents

Learn what mechanical processing is

Mechanical processing mostly uses machines, technology and physical principles to make finished products from raw materials. Mechanical processing is increasingly achieving high precision and saving time thanks to the remarkable development of technology.

Mechanical processing has many applications in life, so it is focused on investment for development. Raw materials, especially metals, through the mechanical processing process will become useful items in life and production.

Classification of mechanical processing in Binh Duong

Non-blank mechanical processing (punching, hot machining, pressure)

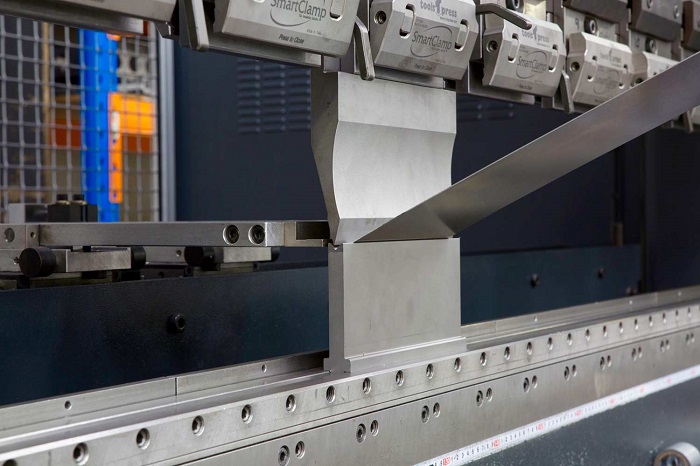

Non-blank machining is also known by familiar names such as punching machining, hot machining and pressure machining. This machining process will keep the metal block intact without having to separate it from the machine. Machining operations include casting, hot stamping, cold stamping, rolling, welding, forging, drawing, pressing, etc.

Non-blank machining is often used for products that do not require high precision and accuracy. To increase the precision and smoothness, the initial product will be applied with additional machining methods such as laser cutting, planing, drilling, broaching, etc.

Machining of workpieces

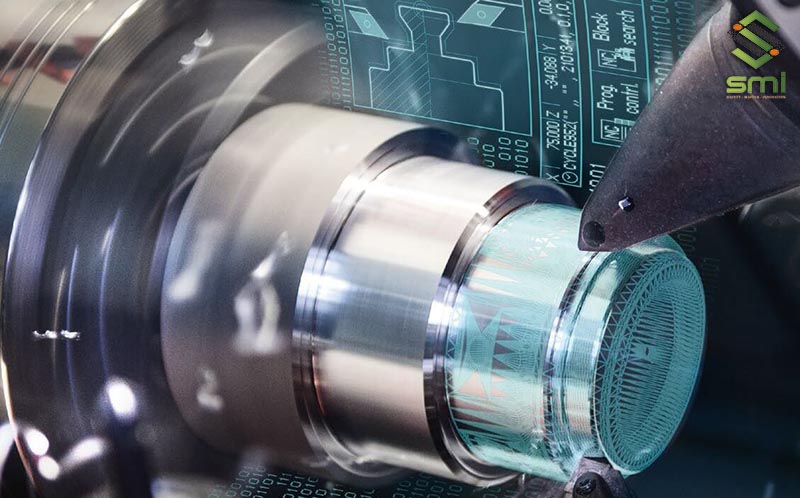

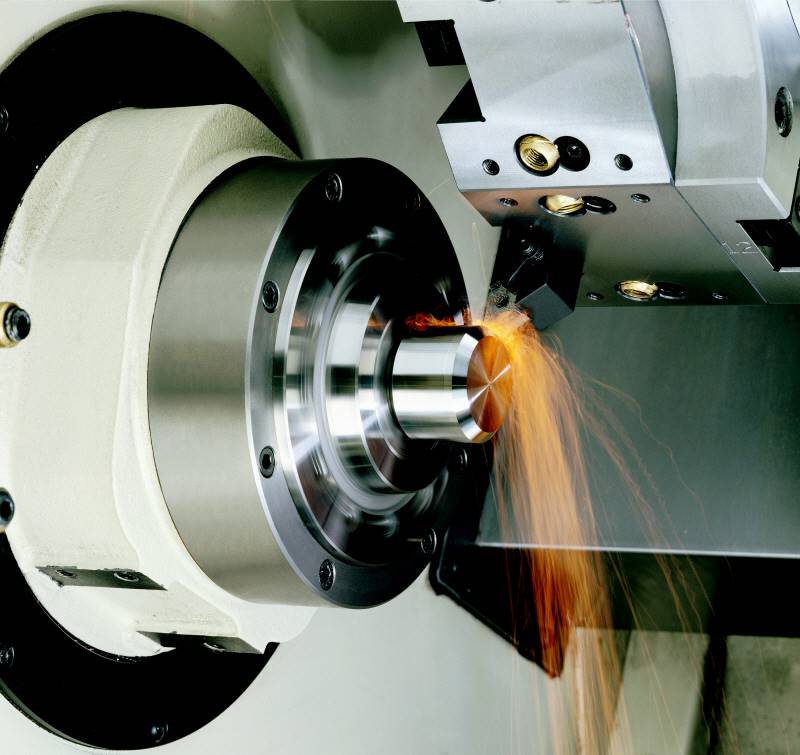

Machining workpieces is a machining method with the support of machines. During the machining process, a certain amount of metal will be discharged. Workers will be able to apply a number of machining methods such as turning, grinding, boring, planing, milling, etc.

This machining method is often applied to products with high requirements of shape, size, smoothness and precision. The worker will apply mechanical machining methods on the available blank to create the product according to the design drawing.

Evaluation of mechanical processing quality in Binh Duong

*** Please refer to more Cơ sở gia công cơ khí tại bình dương

Contact now:

EINTEK ENGINEERING CO., LTD

Address: No 02, Street No 07, Long Binh ward, Ho Chi Minh city

Email: info@eintek.com.vn

Mobile: (+84) 944 244 468

Website: www.eintek.com.vn