In today’s industrial production, fixtures have become essential and important equipment. Thanks to them, productivity is improved and labor is significantly reduced. Fixtures for drilling machines are also such a product. Let’s learn more about this equipment through the following article.

Contents

What is a machining fixture on a drilling machine?

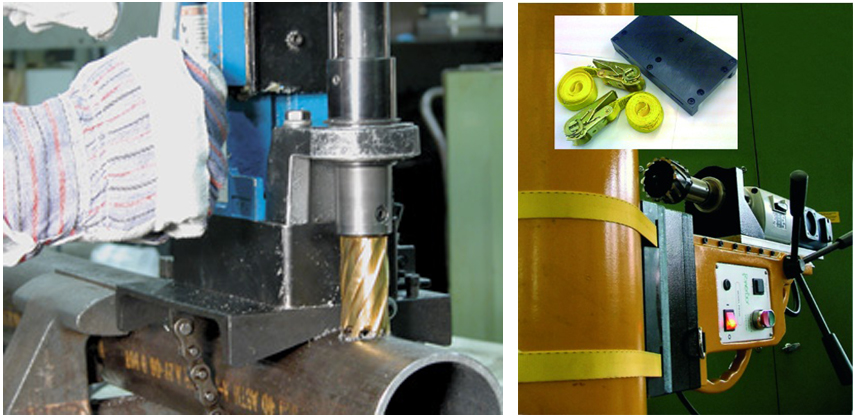

Machining fixtures on drilling machines are also known as drilling fixtures. This is a type of fixture used on drilling machines in the mechanical field. It has the function of clamping the workpiece when drilling holes, and at the same time determining the relative position of the workpiece and the cutting tool. In addition, it also has auxiliary tools to clamp the knife when machining such as quick clamping head and drill sleeve.

What types of fixtures are there on drilling machines?

There are many types of jigs for drilling machines, but based on the structure, working principle and method of setting, they can be divided into 3 types. These types all limit the workpiece’s freedom from 5 to 6 degrees to ensure accuracy when determining the center hole:

- The first type is the rotary drilling fixture. Its structure consists of 10 parts: Fixture body, locating pin shaft, division, pin spring, adjusting pin, fixed guide tube, guide plate, detail, washer and nut. The rotary drilling fixture uses the complete positioning method (limiting all 6 degrees of freedom of the detail).

- The second type is the drilling fixture with removable guide plate. Its structure consists of 14 parts: Fixture body, workpiece, backing plate, guide plate, guide tube, center shaft, side trim pin, eccentric shaft, hook washer, clamping pin, screw, nut and pin. The drilling fixture with removable plate also uses the complete positioning method.

- The third type is the drilling fixture with hanging guide plate. Its structure consists of 9 parts: Workpiece, V block, base, guide plate, guide column, adjusting screw, hanger, bushing and spring. Drilling fixtures with suspended guide plates only require 5 degrees of freedom restraint of the workpiece.

Where to order machining fixtures on drilling machines?

EINTEK accepts processing of fixtures on drilling machines upon request

EINTEK is a unit specializing in processing jigs on drilling machines according to requirements in Binh Duong. In addition, we also accept processing a variety of other mechanical products. With modern processing methods and advanced machinery. Our processed products and details have high precision and aesthetics.

Advantages of manufacturing machining fixtures on drilling machines at EINTEK

Contact

EINTEK ENGINEERING CO., LTD

Address: No 02, Street 07, Long Binh ward, Ho Chi Minh city

Email: info@eintek.com.vn

Mobile: (+84) 944 244 468

Website: https://eintek.com.vn/