There are many types of fixtures today, bringing convenience to users as well as contributing to improving production efficiency such as: milling fixtures, broaching fixtures, inspection fixtures, assembly fixtures, welding fixtures, etc. In the following article, we will help you understand more about a quite important type of fixture in hole machining, which is the drilling fixture or also known as the hole machining fixture, let’s find out.

What kind of accessories are hole machining fixtures?

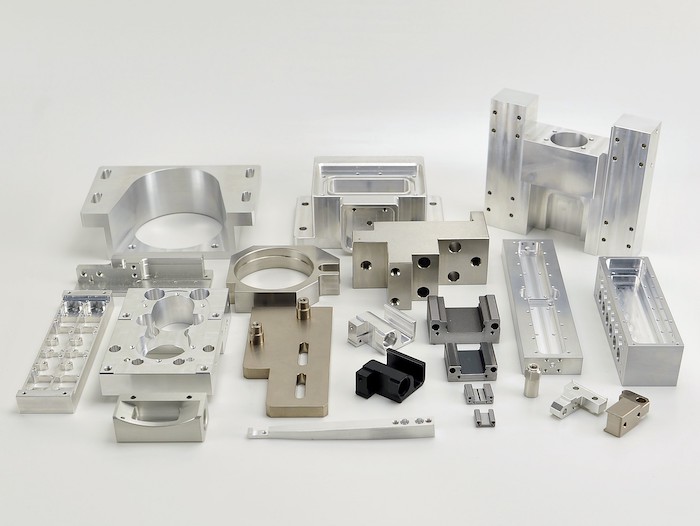

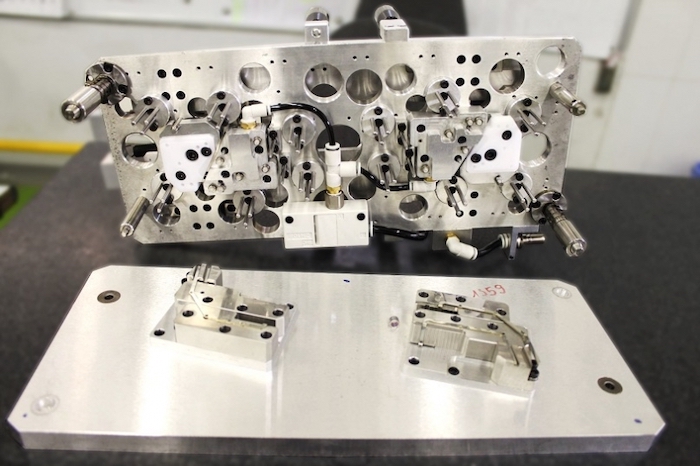

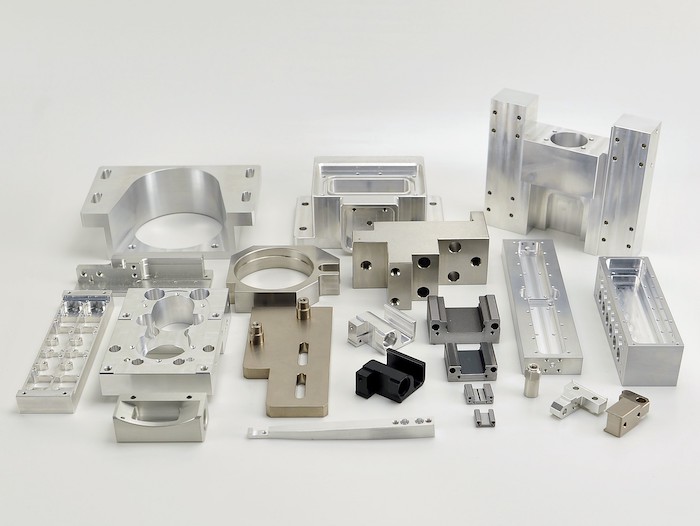

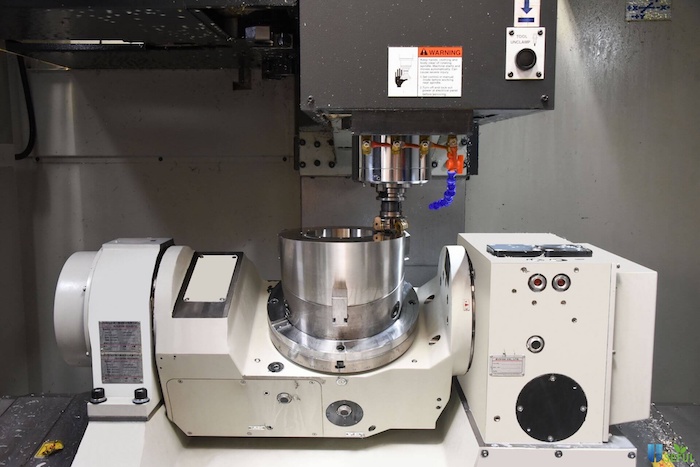

Hole machining fixtures, also known as drilling fixtures, are accessories used on drilling machines to determine the relative position between the workpiece and the machining tool, and at the same time perform the task of clamping the workpiece during the hole machining process.

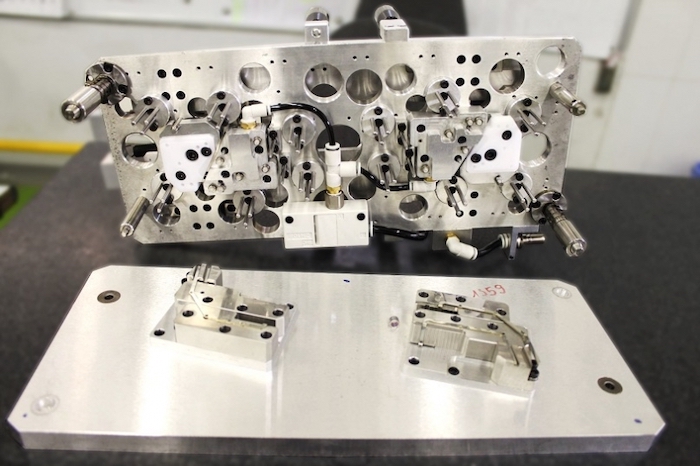

Basic structure of hole machining fixture

A hole machining fixture usually has the following basic structure:

- Fixture foot

- Standard

- Plate

- Guideplate

- Guide tube

- Center shaft

- Clamp

- …

Requirements of a hole machining fixture

A quality hole machining fixture must meet the following requirements

Requirements for clamping mechanism

When clamping, the fixture must hold the correct position of the part to be machined, the clamping force must be sufficient but not deform the workpiece, the fixture structure must be compact and easy to operate.

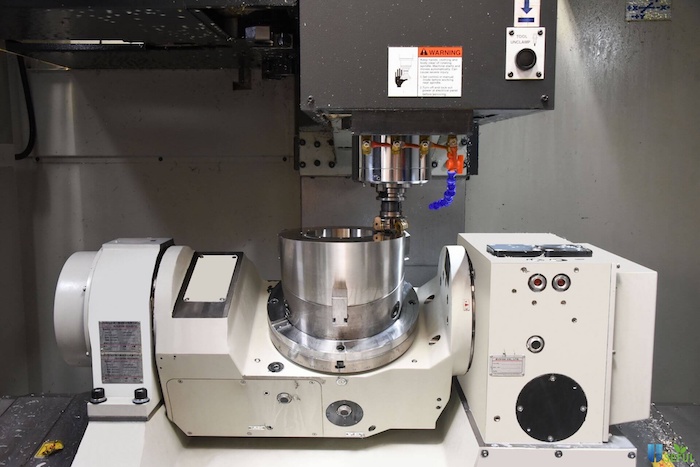

Requirements for guiding mechanism

The guiding mechanism is an important part, especially when machining small holes. The guiding mechanism helps the worker determine the direct position of the drill bit, helping to increase the rigidity of the drill bit when machining.

Other structural requirements

In addition to ensuring the clamping and guiding mechanisms, the hole processing fixture must meet other structural requirements, typically: force transmission, drill bit comparison, etc.

In addition, another requirement for the hole processing fixture is that the external parts of the fixture must not have sharp edges to ensure the safety of the worker.

Notes when using hole machining fixtures

- When adjusting or changing the machine table, do not change the position of the fixture

- Use specialized tools when assembling the parts on the fixture.

- The fixture must achieve static and dynamic balance.

Where to buy hole processing fixtures to ensure quality?

With separate functions as well as the required standards of a hole processing fixture, consumers should buy products from reputable suppliers and Eintek will be a suitable and reliable choice for you if you do not know where to buy hole processing fixtures.

We are a unit specializing in providing industrial equipment, accessories as well as long-term mechanical processing services, and are partners of many customers across the country.

The products we provide always ensure quality standards as well as reasonable prices, so customers can completely rest assured when using the products we provide.

Therefore, please contact our Eintek team immediately to receive the earliest support on the product.

*** You can see more of our other services:

Contact now:

Address: No 02, Street 07, Long Binh ward, Ho CHi Minh city .

Email: info@eintek.com.vn

Mobile: (+84)944 244 468

Website: https://eintek.com.vn