Talking about the mechanical industry, this is the “backbone” of the economy anywhere and is increasingly interested, invested and developed in cities. Especially in Binh Duong, the investment fever in the mechanical processing industry from production to distribution is very interested by domestic and foreign enterprises. Facing the development of the industry, precision mechanical processing in Binh Duong is increasingly invested and developed rapidly.

Contents

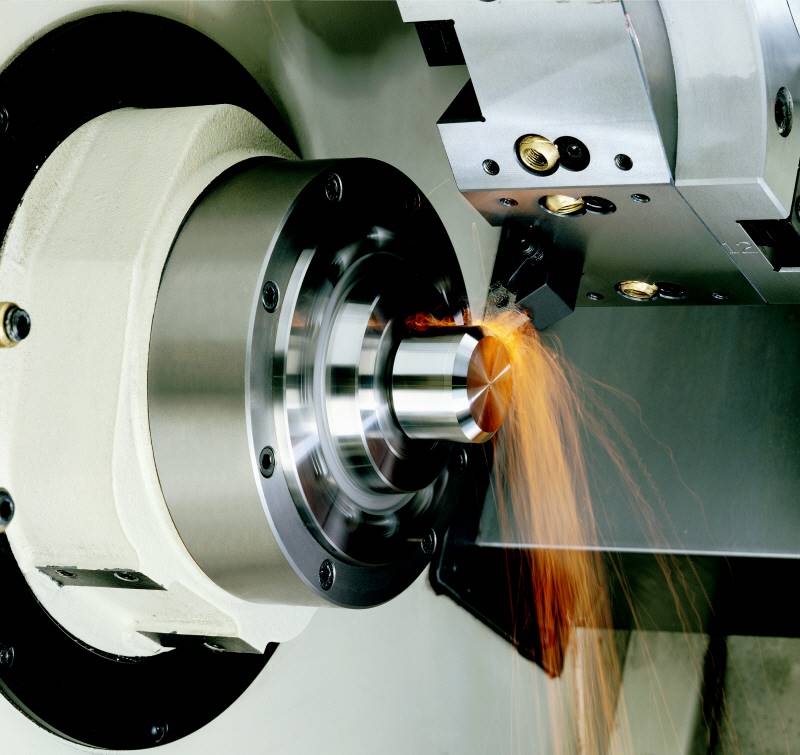

Mechanical processing industry

The precision mechanical processing industry in Binh Duong contributes greatly to the industrialization and modernization of the country. The mechanical field increasingly brings many benefits to investors, is considered one of the fields with remarkable progress in science and technology and receives much attention from the Party and the State.

What is a precision machining workshop?

When it comes to precision machining, it is seen that its application in practice is extremely useful. That is, it is possible to use physical experience to create products and equipment that are considered as human labor tools in the modern world. With techniques that require high expertise to achieve product accuracy, precision machining is an essential part of the production process.

Mechanical processing methods in Binh Duong

Mechanical processing methods are very diverse, but mainly three main types are applied:

- Precision mechanical processing: performed by specialized laser cutting machines, which can be automatically controlled through CNC software, combined with skillful techniques and many years of experience of the workshop’s mechanical team, the output products have high precision according to the customer’s model and design.

- Mechanical processing: manual method, requiring a team of mechanical workers with activities such as milling, welding, planing, flat grinding, round grinding, …. to create products according to customer requirements.

Types of materials used in the workshop for precision mechanical processing in Binh Duong

- Specific alloy steels are: S45C, S50C, SKD61, SKD11, M2, D2.

- Stainless steel lines: inox SUS201, SUS304, SUS420, SUS430, …

- Regular steel: CT3, SS400.

- Some colored metal materials such as: red copper, brass, aluminum or Titanium.

- Plastic materials: POM, PE, PU, MC, PTFE, HDPE, …

- Some non-metallic materials such as tweezers.

- In addition, there is additional support from: chrome plating, powder coating, … to ensure product safety and quality.

Advantages of choosing a precision mechanical processing workshop in Binh Duong – Eintek

***See more: Xưởng gia công cơ khí tại Bình Dương

Contact now:

EINTEK ENGINEERING CO., LTD

Address: No 02, Street No 07, Long Binh Ward, Ho Chi Minh city

Email: info@eintek.com.vn

Mobile: (+84) 944 244 468

Website: www.eintek.com.vn