As an accessory used to fix and locate materials and machined parts, fixtures play an extremely important role in all machining operations, especially machining on milling machines. So what exactly is that important role? The following article on machining fixtures on milling machines will help you better understand the role of this accessory, let’s find out.

Contents

Structure and effects of machining fixtures on milling machines

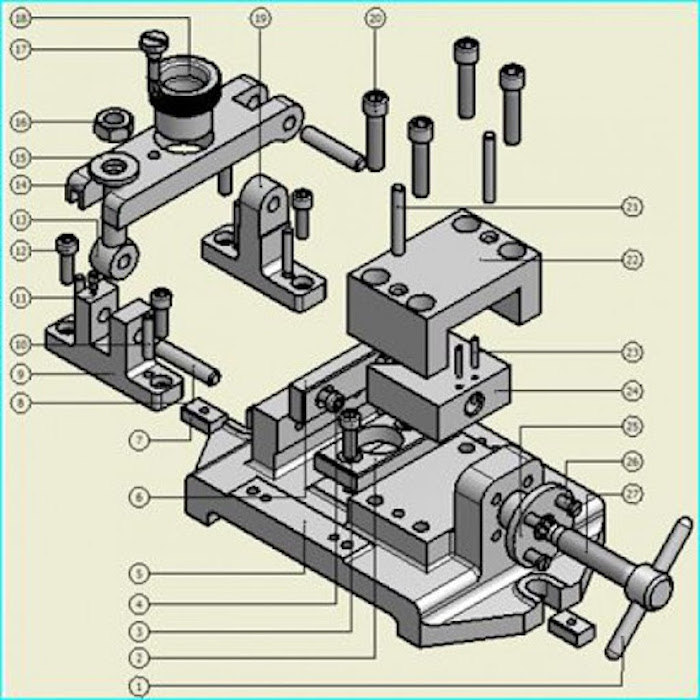

Basic structure of accessories

There are many types of fixtures, each with its own unique design. However, in general, this type of accessory has the following basic structure:

- Body and base

- Positioning and clamping parts

- Positioning and clamping mechanism to the machine

- Other mechanisms: power transmission, guidance, tool comparison, rotation,…

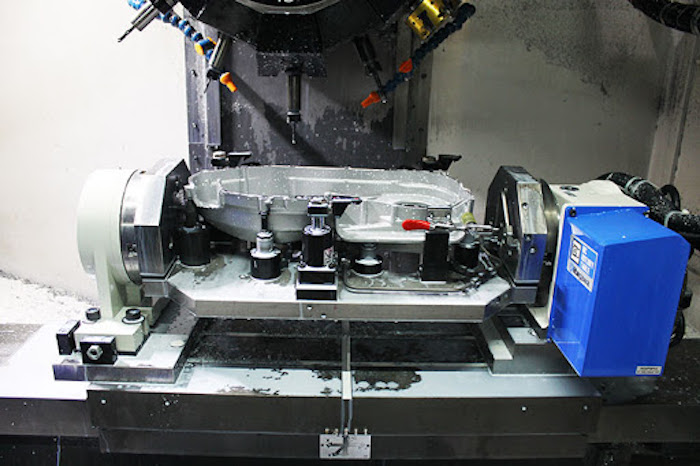

What is the specific function of the Machining Fixture on the milling machine?

So what is the function of a milling machine fixture?

- Determine the location of the part to be machined and guide the machining operation

- Fix the machining position by clamping tightly to prevent the machined part from being affected by external forces.

- Support machining movements for complex machined parts.

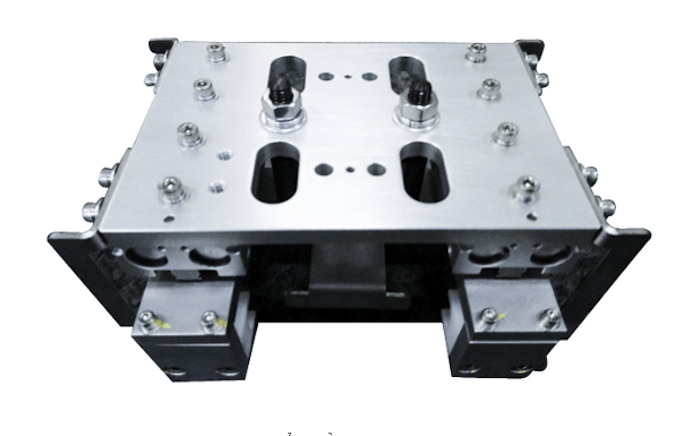

Introducing the types of machining fixtures on milling machines today

Eintek – a facility specializing in providing quality, good-priced milling machine jigs

As a facility specializing in distributing industrial equipment, accessories, and machine accessories, Eintek will be the destination that brings you satisfaction if you are looking to buy milling machine processing fixtures:

- Enthusiastic consulting team

- Diverse and high-quality products

- Good prices

- Technical support with a lot of experience.

*** See more:

Contact now:

EINTEK ENGINEERING CO., LTD

Address: No 02, Street 07, Long Binh ward, Ho CHi Minh city

Email: info@eintek.com.vn

Mobile: (+84) 944 244 468

Website: https://eintek.com.vn/